Product center

Home > Product center > Environmentally-friendly paint spray booth Environmentally-friendly paint spray booth

Dry paint fog treatment spray booth

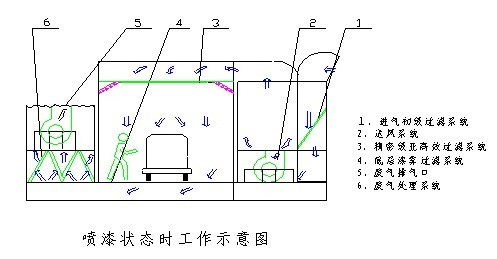

[Working principle of equipment]

The working principle of try spray booth: The outdoor air, after being filtered by the primary filter screen, is sent by the fan to the top of the spray booth, adjusted by the flow equalizer, and sent into the booth after passing the precision sub-high efficient filter layer at the top, and streams top down in laminar flow, where the dust content of air is ≤1.5mg/m3 and maximum particle diameter ≤5μm. A work piece is put into an equalized laminar flow with certain wind speed, making waste fog spilled during paint spray pressed into the filter at the bottom for collection and treatment purpose. The over-sprayed paint fog and the organic gas volatilizing during spraying are quickly sucked into the paint fog treatment system below the gridding: The glass fiber filter felt will remove part of the paint fog, and the activated carbon will remove the organic dissolvent in the air stream. The treated air will be exhausted by into the atmosphere by the exhaust system via the exhaust vent, thus to ensure that the emissions are in compliance with GB16297 -1996 General Emissions Standard for Atmospheric Pollutants.

[Purpose of equipment]

It’s suitable for spray-painting products of small output.

[Equipment structure]

The equipment is composed of the enclosed booth system, the lighting system, the air supply system, the air supply cleaning and pressure-equalizing system, the exhaust system, the waste treatment system, the control system, and the track platform truck, etc.

[Schematic diagram of equipment]

|

噴漆狀態(tài)時(shí)工作示意圖

|

Schematic diagram for working state of paint spray

|

|

進(jìn)氣初級過濾系統(tǒng)

|

Air inlet primary filter system

|

|

送風(fēng)系統(tǒng)

|

Air supply system

|

|

精密級亞高效過濾系統(tǒng)

|

Precision sub-high efficient filter system

|

|

底層漆霧過濾系統(tǒng)

|

Bottom paint fog system

|

|

廢氣排氣口

|

Waste gas exhaust vent

|

|

廢氣處理系統(tǒng)

|

Waste gas treatment

|